Why the Foundation Matters for Your Synthetic Lawn

Artificial grass layers are the hidden components that determine if your synthetic lawn will last for decades or fail within a few years. While most homeowners focus on the turf’s appearance, the secret to a long-lasting fake lawn lies in the foundation you can’t see. Cutting corners on base preparation leads to puddles, wrinkles, and weeds.

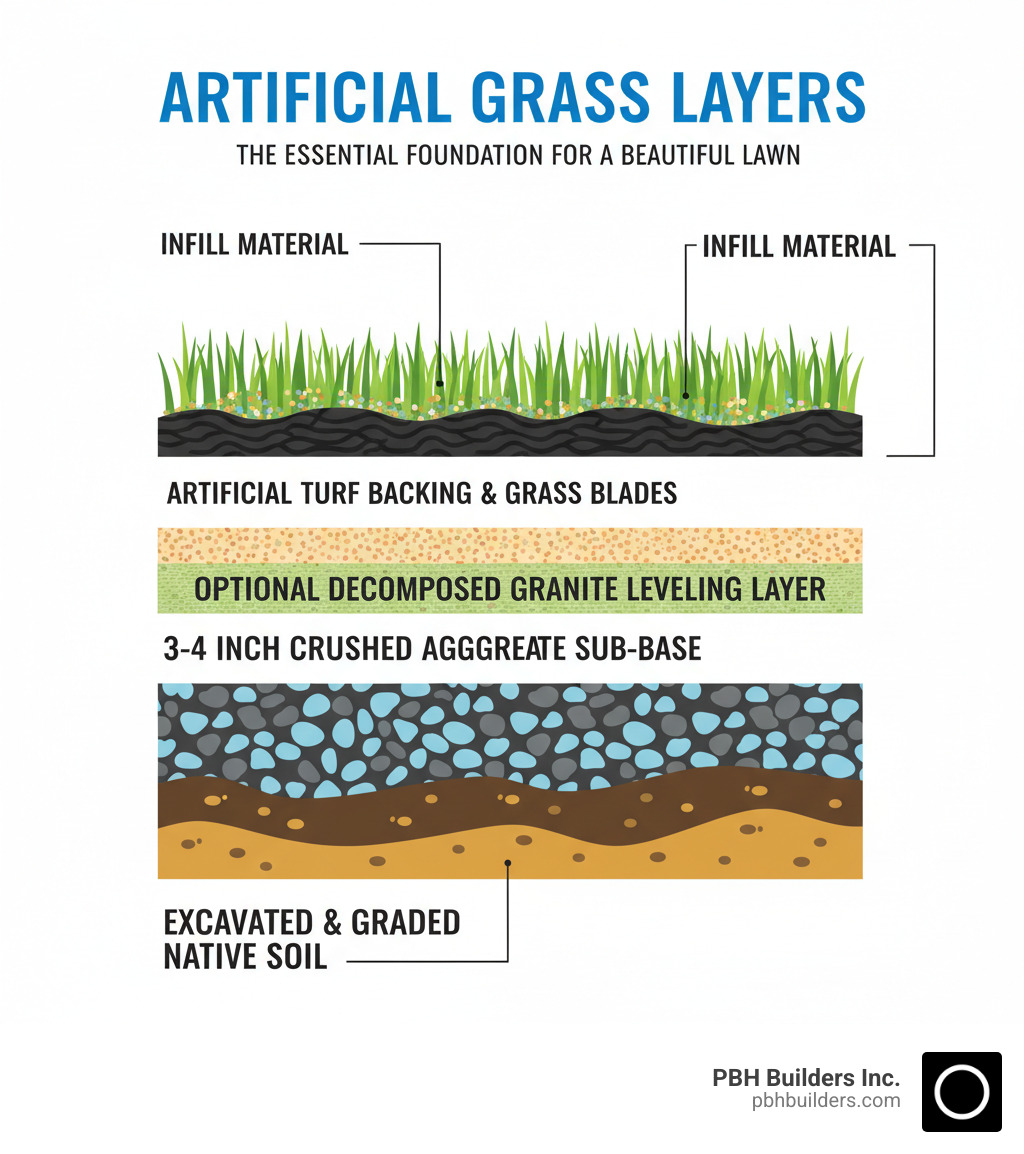

The essential artificial grass layers include:

- Native soil preparation – Excavated and graded for proper drainage

- Sub-base layer – 3-4 inches of crushed aggregate for stability

- Leveling layer – 1-2 inches of sand or decomposed granite for a smooth surface

- Weed barrier (optional) – Permeable fabric to prevent unwanted growth

- Artificial turf – The visible grass surface

- Infill material – Sand or rubber granules to support grass blades

Think of it like a house foundation—it’s unseen but critical. The sub-base provides drainage and prevents settling, while the leveling layer creates a perfectly smooth surface. In San Diego’s climate, proper drainage is vital to prevent your lawn from becoming a swamp after rain or developing odors.

This guide breaks down each layer of a proper artificial grass installation, explaining which materials to use, the required depths, and how to adapt the base for special uses like pet areas or putting greens.

Quick artificial grass layers definitions:

The Essential Artificial Grass Layers: From Ground Up

Each layer beneath your turf plays a specific role in a successful installation. Skipping one can lead to problems down the road.

Native Soil and Excavation

Every installation begins by preparing the existing ground. We remove old grass, roots, rocks, and debris to create a clean slate.

Next is excavation. For most residential lawns, we dig down 3 to 4 inches. Some projects, like those with poor drainage or thick natural grass, may require up to 12 inches. Putting greens need about 6 inches for a more refined base.

A common mistake is making the area perfectly flat. We grade the soil with a slight slope to direct water away from your house and toward drainage areas. This is crucial in San Diego to prevent puddling during intense rains. Finally, we cap unused sprinkler heads and move any wiring. This is also the perfect time to consider a complete landscape design overhaul.

The Sub-Base: Foundation for Success

The sub-base is the most critical of the artificial grass layers. It provides rock-solid stability and ensures proper drainage. It distributes weight from foot traffic and furniture to prevent dips and valleys, and it creates a channel for water to escape.

We use crushed stone or gravel, typically 3/4 inch or smaller, as these angular pieces lock together when compacted. For professional installations, we use Class II Road Base, the gold standard for compaction and long-term stability.

This layer should be 3 to 4 inches deep for standard lawns, but high-traffic or poor-drainage areas may need up to 12 inches. A weak sub-base will lead to a lumpy, poorly draining lawn.

The Leveling Layer: Creating a Smooth Surface

After the sub-base provides strength, the leveling layer adds the final polish: a perfectly smooth surface for the turf. This layer fills in minor imperfections, ensuring a flawless, professional look.

We use 1 to 2 inches of coarse builders sand or decomposed granite (DG). Sand provides a fine-grained surface, while DG is a DIY-friendly option that compacts well with a stabilizer. For putting greens, we add a 1/2-inch layer of ultra-fine crusher fines for a billiard-table-smooth surface. This material is carefully spread, raked, and compacted, as any bump will show through the finished lawn.

The Weed Barrier Debate: Is It Always Necessary?

A weed barrier is a permeable fabric placed between the leveling layer and the turf to block weeds while allowing water through. For many general landscaping projects, it adds a helpful layer of protection.

However, the barrier can sometimes trap moisture and organic debris, which may lead to bacterial growth and odors. This is a particular concern for pet owners in San Diego’s climate. For pet areas, we often skip the fabric and instead apply a weed preventer directly to the native soil before building the base. This provides weed control without the risk of trapped moisture. The necessity of a weed barrier depends on your specific situation, and we recommend the best solution for each project.

Choosing Your Base Materials: A Head-to-Head Comparison

Choosing the right materials for your artificial grass layers is key to a successful project. Each type of aggregate has unique properties affecting drainage, stability, and ease of use.

Comparing Common Base Materials

- Crushed stone or gravel (3/4 inch or smaller) is the workhorse for turf installations. It offers excellent drainage and, when compacted, creates a stable foundation. It’s a mid-range cost option but can shift if not compacted thoroughly.

- Class II Road Base is the professional’s choice. Used for building roads, it contains a mix of aggregate sizes that lock together for incredible stability and excellent drainage. It’s what we use at PBH Builders Inc. for most projects, though it can be difficult for DIYers to source and requires heavy machinery.

- Decomposed granite (DG) is a DIY favorite. It’s easy to handle and creates a very smooth surface, especially when mixed with a stabilizer. It drains well and is comparable in cost to crushed stone, but it can be dusty during installation.

- Paver base is a finer aggregate that provides a stable, compactable surface with good drainage. It’s more expensive, so it’s typically only used when working over pre-existing hardscaping.

- Sharp, coarse builders sand is best used as a leveling layer on top of a compacted sub-base. It is not a standalone base material, as it can shift and erode without proper containment.

For most residential projects, crushed stone or DG is sufficient. For professional-grade durability, Class II Road Base is the superior choice.

The Critical Role of Compaction

Spreading the base material is not enough. Compaction is the non-negotiable step that turns loose aggregate into a solid foundation. Without it, your lawn will quickly develop low spots, puddles, and wrinkles as the base shifts and settles.

Compaction forces the aggregate particles together, eliminating air pockets and creating a dense, unified surface that won’t move. For professional results, we use a plate compactor. This machine’s vibrations pound the material into a solid base. We lightly moisten the material to help it bind, then make multiple passes with the compactor, filling any low spots and re-compacting until the surface is uniformly dense. We aim for 90-95% compaction.

For small areas, a hand tamper can be used, though it is more labor-intensive. The bottom line is that proper compaction is the single most important step for ensuring your artificial lawn remains flat, stable, and beautiful for years. It’s what separates a professional installation from an amateur one.

Adapting Your Base for Specialized Applications

Not all artificial grass installations are the same. The artificial grass layers must be modified for specific uses, from pet runs to putting greens.

Pet Areas: Prioritizing Drainage and Odor Control

For pet-friendly lawns, the base must be optimized for superior drainage and odor control. We often skip the traditional weed barrier, which can trap odor-causing bacteria, and instead apply a weed preventer to the native soil.

The key is using specialized infills like Zeofill or antibacterial Envirofill sand, which neutralize ammonia from pet urine. For heavy-use areas, we may also recommend fully permeable turf backing and drainage grids like AirDrain. These create an air gap for improved water and air flow, resulting in a clean, fresh-smelling lawn. More info about low maintenance landscaping

Playgrounds and High-Traffic Zones

Playgrounds require layers focused on safety and durability. The most important addition is a shock pad made from recycled rubber or foam, installed over the base and under the turf. This provides cushioning to meet fall height safety standards.

For high-traffic zones or areas that support vehicles, we build a more robust base using Class II Road Base. For drivable surfaces, we integrate geotextile permeable pavers on top of the base to distribute weight and prevent ruts.

Slopes, Hills, and Retaining Walls

On sloped terrain, we use specialized techniques to prevent the base from shifting. For gentle slopes (up to 15 degrees), we lay wire mesh over the native soil before adding the base. For steeper slopes, we install honeycomb-like stabilization membrane cells to lock the base material in place. Our hardscaping services ensure seamless transitions between turf and features like retaining walls.

Putting Greens: The Pursuit of Perfection

A backyard putting green demands absolute precision to ensure a true ball roll. We excavate deeper (around 6 inches) to build a multi-layered base, typically including clear crush, landscape fabric, and several inches of crush and fines to create contours. Each layer is carefully compacted and leveled, with a final half-inch layer of ultra-fine crusher fines to create a perfectly smooth surface.

Installing Over Concrete or Pavers

You can install artificial grass over an existing concrete or paver surface. First, we assess the surface for proper drainage. If needed, we install drainage tiles or a shock pad to lift the turf, allowing water to flow freely and adding cushioning. The turf is then secured around the perimeter. Our San Diego paver installers can recommend the best approach for your existing hardscape.

The Finishing Touches: Infill and Securing Your Turf

After the base is prepared and the turf is laid, infill is the final crucial step. This granular material is spread over the turf and brushed into the fibers.

Understanding the Purpose of Artificial Grass Layers of Infill

Without infill, grass blades would flatten, the turf could wrinkle, and the backing would be exposed to damaging UV rays. Infill serves several key purposes:

- Supports grass blades, keeping them upright for a full, natural look.

- Adds weight to the turf, acting as ballast to hold it securely in place.

- Protects the backing from UV degradation, extending the lawn’s lifespan.

- Provides cushioning, making the surface softer underfoot.

- Aids drainage by creating channels for water to flow through to the base.

Recommended Depths for Artificial Grass Layers of Infill and Application

The right infill depends on the lawn’s intended use.

- Silica sand is the most common, cost-effective choice for general landscaping.

- Rubber crumb offers superior cushioning, making it ideal for playgrounds.

- Zeolite is a natural mineral that absorbs and neutralizes pet odors, perfect for pet areas.

- Envirofill and Durafill sand are premium, antibacterial options safe for kids and pets, offering excellent performance and odor control.

Proper application is key. First, we use a power brush to stand the grass blades up. Then, we use a drop spreader to apply the infill evenly. The goal is to fill the turf so the granules reach about two-thirds of the way up the blade height. Finally, we brush the turf again to work the infill down to the base. This process supports each blade and adds the necessary weight to keep your lawn pristine for years.

Frequently Asked Questions about Artificial Grass Base Layers

What is the best base material for artificial grass?

The “best” material depends on the project. For professional installations, Class II Road Base is the gold standard for artificial grass layers due to its superior stability and compaction. It creates a rock-solid foundation that won’t shift. For DIY projects, decomposed granite (DG) mixed with a stabilizer is an excellent, more user-friendly alternative that still provides a stable, smooth surface when compacted properly.

How deep should the base for artificial grass be?

The total base depth for artificial grass layers is typically 3 to 6 inches. A standard residential lawn requires about 3 to 4 inches of a sub-base (crushed aggregate) topped with a 1 to 2-inch leveling layer (sand or DG). Specialized applications like putting greens or high-traffic areas may require a deeper base of 6 inches or more to ensure proper performance and drainage.

Can you install artificial grass directly on soil?

No. Installing artificial grass directly on soil is a recipe for failure. Without the proper artificial grass layers, the ground will settle unevenly, creating bumps and dips. Drainage will be poor, leading to puddles and potential odors. Weeds will grow through the turf’s backing, and the lawn’s lifespan will be significantly shortened. A properly prepared and compacted base is absolutely essential for a beautiful, long-lasting artificial lawn.

Conclusion: Building a Lasting Lawn from the Ground Up

Your artificial lawn’s secret to longevity isn’t the turf itself—it’s the hidden artificial grass layers underneath. From excavation and grading to the final layer of infill, each step works to create a beautiful and functional outdoor space.

A well-compacted sub-base provides stability, a leveling layer ensures a smooth surface, and specialized infills support the grass blades while adding weight and cushion. Understanding these layers allows you to adapt your installation for any need, whether it’s a pet-friendly run, a safe playground, or a perfect putting green. In San Diego, where we value water-wise solutions, a properly installed artificial lawn offers a lush green space without the maintenance, but only if it’s built on a solid foundation.

Cutting corners on base preparation will cost you more in the long run, leading to poor drainage, an uneven surface, and a shortened lifespan for your turf. The foundation is everything.

For expert artificial turf and pavers installation in San Diego, the professionals at PBH Builders Inc. ensure every layer is perfectly installed for a durable result. We understand your outdoor space is an investment, and we build it to last—because what’s beneath the surface matters most.